Navigating the Packaging and Packaging Waste Regulations: PPWR, EPR & DRS

Stuart McCaig

Managing Director & European Product Manager

Ultrapolymers Ltd

Stuart is the Managing Director of Ultrapolymers Ltd, bringing over a decade of experience in polymers. He is deeply passionate about sustainability and cultivating innovation in the circular economy, supporting customers from supply through to production, helping them reduce their carbon footprint and achieve their sustainability goals and working with household known brands, including Hozelock and Numatic.

Prefer to listen to the audio version of this article?

What is the Packaging and Packaging Waste Regulation? What is the PPWR?

The European Union (EU) and the United Kingdom (UK) are driving towards a circular economy for packaging, but regulatory approaches differ from country to country. The Packaging and Packaging Waste Regulation (PPWR) replaces a patchwork of national rules with a harmonised approach to packaging across the EU, extending recycled-content requirements to almost all plastic packaging. The key objectives of the EU PPWR are to:

- Cut packaging waste by 5% by 2030, per capita, and by 15% by 2040;

- Ensure all packaging is recyclable by design by 2030, with practical recycling by 2035;

- And to have a minimum of 25% recycled plastic in PET beverage bottles by 2025 and higher thresholds for other formats by 2030 and 2040.

However, each country is retaining specific national taxes and deposit return schemes alongside the core PPWR obligations. And the UK is developing separate systems to trade with each nation, defining its own thresholds and enforcement mechanisms.

What is the current state of PPWR?

The Packaging and Packaging Waste Regulation, PPWR, entered into force on the 11th of February 2025, with an 18-month transition period before obligations begin applying from August 2026. However, the timeline extends well beyond that date, with critical milestones through to 2040 that will progressively tighten requirements.

- 2026: The EU will enforce harmonised Extended Producer Responsibility (EPR) frameworks. From this point, your packaging must be designed for recycling, clearly labelled, and covered by appropriate EPR fees.

- 2028: By the end of 2028, all packaging must carry standardised recycling and disposal labels across the EU. This eliminates the current patchwork of national labelling schemes and ensures consumers across borders receive consistent information.

- 2030: All packaging must be recyclable by design, and mandatory recycled-content thresholds apply to specific packaging formats. For plastics, this means meeting minimum post-consumer recycled (PCR) content levels that vary by packaging type, e.g. beverages, cosmetics, detergents, and other contact-sensitive formats all have distinct requirements.

- 2030 targets also include 90% separate collection for plastic beverage bottles, meaning 90% of all plastic beverage bottles must be collected by local authorities separately from general waste and sent to a dedicated recycling stream, rather than mixed waste. Separate collection helps keep the feedstock clean and as high-quality as possible.

- 2035: Moving beyond design criteria, packaging must be recyclable at an industrial scale. Proven collection, sorting, and reprocessing infrastructure must be in place and function effectively across Europe.

- 2040: Recycled content requirements increase significantly, raising PCR percentages across all plastic packaging formats.

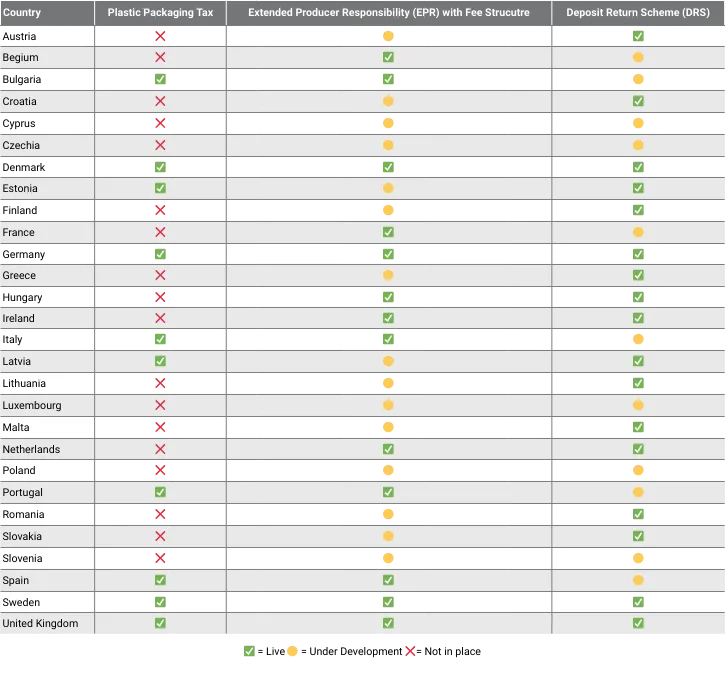

Country Regulations Across Europe

Packaging taxes and levies vary significantly across the EU and UK. Still, the direction is consistent: using virgin plastic in packaging will cost more in the future, with financial penalties, while complying with new initiatives by using recycled content instead will be more cost-effective. Understanding this landscape is essential for calculating the actual cost of packaging choices.

Does PPWR apply to the UK? What are the UK Packaging Regulations?

The UK shares the EU's ambitions for a circular packaging economy, but has still developed its own system. In 2022, the UK Plastic Packaging Tax (PPT) was introduced in April 2022, with a £223.69 per tonne tax (applied from April 2025) on packaging containing less than 30% recycled plastic, creating a strong financial incentive to meet this threshold. The local government is also implementing Extended Producer Responsibility (EPR), transferring waste management costs from consumers to producers. Unlike the EU’s PPWR, the UK has not set a fixed date for universal recyclability, and Deposit Return Schemes (DRS) are progressing at different rates across the UK and Northern Ireland, making compliance more complex for businesses operating nationwide.

For companies trading between the EU and UK, this divergence means navigating two distinct regulatory frameworks: PPWR in the EU27 and PPT/EPR in the UK, each with its own reporting, labelling, and fee structures. The most effective strategy is to design packaging to the stricter standard, the PPWR’s 2030 recyclability and recycled content requirements, which will usually exceed the UK’s 30% PPT threshold and qualify for EPR fee reductions in both regions. This unified approach simplifies supply chains, reduces SKU complexity, and minimises the financial and operational risks of non-compliance, such as restricted market access and penalties.

How to Comply with New Regulations

As businesses come to face sustainability, the trick is not to treat these as regulatory hurdles but as opportunities to future-proof operations, enhance brand positioning in the market and avoid costly levies.

The timeline to 2030 may seem distant, but the decisions you make today determine your compliance position, cost structure, and market access in five years. Early action reduces risk, avoids last-minute redesigns, and captures the financial benefits of recycled content before competitors.

Large companies should audit all packaging, align designs to meet PPWR’s strict recyclability and recycled content standards to facilitate cross-border trade, engage suppliers to provide certified recycled content with full traceability, and invest in systems to track data for Digital Product Passports.

Small and medium enterprises should simplify packaging by reducing materials and layers, check and register for EPR thresholds early, and source from certified suppliers to lower EPR fees, improve recyclability, and keep pace with increasing regulatory and data requirements.

Packaging converters must ensure their products meet both PPWR and UK PPT requirements by embedding design-for-recycling into their processes, training teams on mono-material solutions, and providing robust traceability documentation and certifications as standard.

The Cost of Inaction

Failing to prepare for PPWR and UK packaging legislation carries real financial and strategic consequences. Packaging that doesn't meet recyclability criteria by 2030 may be prohibited from the market. Products subject to plastic taxes without sufficient recycled content face cost disadvantages that compound across every unit sold.

Beyond direct costs, non-compliance creates supply chain risk. Retailers and brand owners are increasingly requiring suppliers to meet recycled content thresholds and recyclability standards as a condition of doing business. Falling short may mean losing contracts, delaying product launches, or incurring expensive last-minute redesigns.

The regulatory direction is irreversible. Europe and the UK are committed to circular packaging economies, and the policy frameworks to enforce that vision are now in place. The only question is whether your business adapts proactively or reactively.

Why Ultrapolymers?

Ultrapolymers offers a comprehensive service package to help businesses navigate complex PPWR, PPT, EPR, and DRS requirements, including technical support, regulatory documentation, and a portfolio of certified recycled, advanced recycled, and bio-attributed polymers with full traceability.

Our sustainable solutions include mechanically recycled solutions (PP, PE, PET etc.) for secondary packaging, delivering up to 88% carbon footprint reduction and cost savings by avoiding plastic taxes and lowering EPR fees. Also in our growing portfolio are advanced recycled and bio-attributed polymers for food, medical, and cosmetic packaging that meet strict safety and recycled-content mandates.

By partnering with Ultrapolymers, companies benefit from expert guidance, reliable supply chains, and future-proof materials, ensuring compliance, reducing costs, and maintaining uninterrupted market access as regulations evolve toward 2030 and beyond.