Material Selection for Metal Replacement

Antony Robinson

Business Development Manager & Technical Service

Ultrapolymers Ltd

Antony Robinson is a Business Development Manager at Ultrapolymers Ltd with a strong foundation in materials engineering, holding a PhD from his research in metallurgy, fracture mechanics, and polymers. He combines a solid understanding of metal performance with hands-on experience in advanced plastics to guide customers through effective metal-to-plastic transitions. His unique background ensures practical, cost-efficient solutions that balance performance with sustainability.

Avoiding Over-engineering

Choosing the right polymer to replace metal isn’t about matching steel’s mechanical properties on paper. It’s about understanding what the product actually needs to do. Over-engineering a polymer choice can lead to unnecessary cost, complexity, and missed opportunities. Instead, the focus should be on aligning material capabilities with application demands: mechanical performance, chemical resistance, ergonomics, haptics, and sustainability.

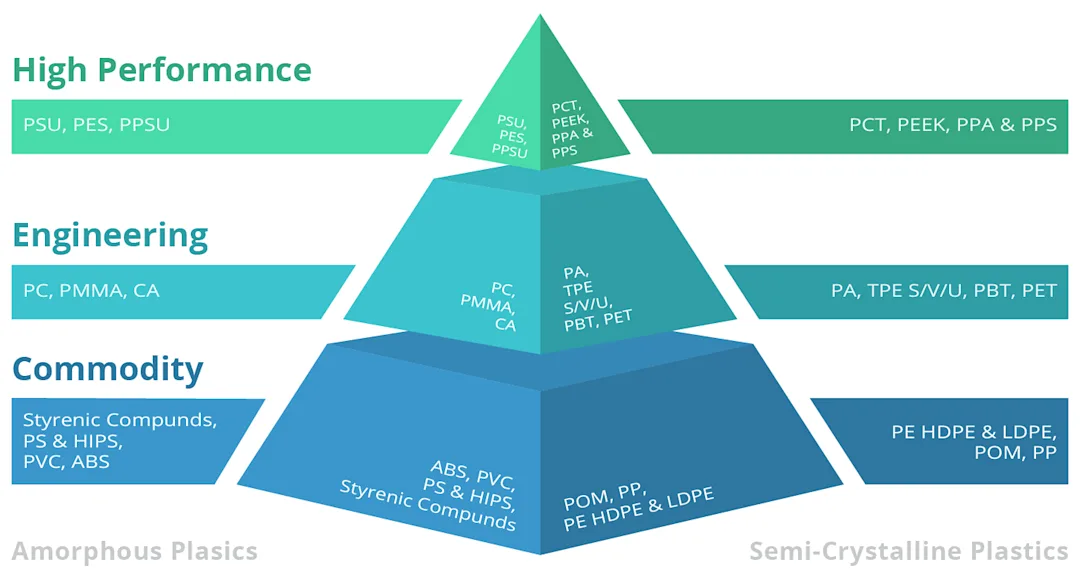

When replacing metal with polymers, people often first consider high-performance polymers. Manufacturers design these materials for the toughest conditions, such as high heat, harsh chemicals, or heavy stress. You’ll find them in jet engines, medical implants, deep-sea equipment, advanced electronics, and spacecraft.

High-performance polymers like PPA, PPS, and PEEK were the first to replace metal, but are costly and complex to process. Now, modern engineering plastics such as PA6/PA66, POM, and PBT deliver high strength, chemical resistance, design flexibility, and easier processing—making them strong competitors to expensive high-performance alternatives.

Mechanical Performance: Fit for Purpose

Over-engineering leads to higher material costs, longer cycle times, and more difficult processing. Engineering polymers like PA6 GF30 or PA66 GF50 offer excellent structural performance without the added cost or complexity of materials such as PPA, PPS, or PEEK. The key is to define the mechanical, thermal, and environmental requirements of the part before consulting data sheets.

- Glass-filled nylons provide excellent stiffness, fatigue resistance, and dimensional stability for demanding applications such as brackets, housings, and supports. TECHNYL® MAX polyamides from DOMO deliver tensile strengths exceeding 200 MPa. DOMO are not just a compounder but a polymersier of nylon that continues to innovate with new chemistries for optimised flow and fibre orientation. This makes the TECHNYL® materials highly suited for replacing steel in applications, including automotive pedal supports or seat bases.

- PPA and PPS push performance further, especially in high-temperature or chemically aggressive environments. However, these are costly and may be overkill for many applications.

Match the material to the job, not the data sheet. A 50% glass-filled PA66 can deliver tensile modulus values exceeding 20,000 MPa. With enhanced design, this has demonstrated being more than enough for many structural applications.

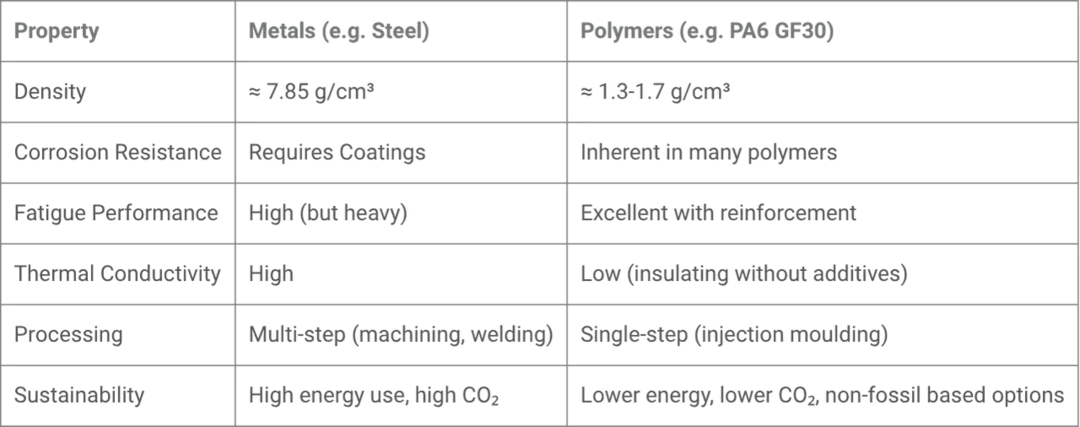

Chemical Resistance: Beyond Corrosion Protection

Polymers have chemical resistance that can outperform metals in specific environments. Semi-crystalline plastics in particular have excellent chemical resistance, hence their use in industrial, automotive, medical and laboratory applications exposed to oils, greases, solvents, acids, alkalis and much more.

- Polyamides (PA6/PA66): Good resistance to oils, fuels, solvents and hydrocarbons. Suitable for automotive, industrial, and consumer goods.

- Polypropylene (PP): Excellent chemical resistance to solvents, fats, acids and bases. Ideal for medical devices, laboratory equipment, and non-structural automotive applications.

Ergonomics and Haptics: Designing for Human Interaction

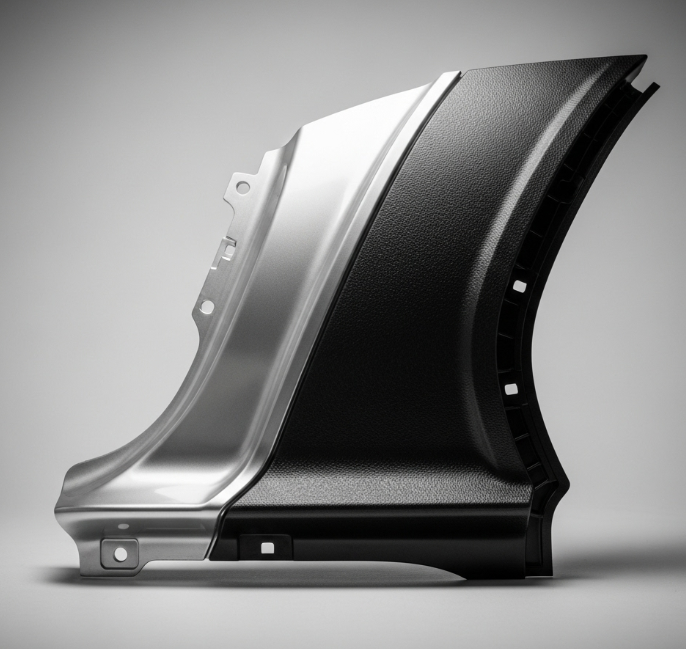

Polymers offer superior ergonomic and tactile benefits compared to metals. The breadth of polymers on offer enables true customisation of a product to meet the exact needs of the end application. To ensure the handle of a medical device is secure, furniture armrests are comfortable, and home appliances are inclusive and easy to use.

- Weight Reduction: The density of plastics makes them significantly lighter than metal, improving user experience and reducing fatigue with home appliances and tools.

- Thermal Insulation: Unlike metals, plastics don’t conduct heat or cold*, enhancing comfort for patients undergoing medical treatment.

- Surface Finish: Additives and pigments achieve gloss, matte, or metallic finishes straight out of the mould to achieve a premium look and feel in cars, cosmetics and consumer goods.

- Soft Touch: Overmoulding and two-shot moulding with soft-touch and grippy TPEs gives a product the perfect feel. Whether it be for comfort or functionality, this is a time and cost-effective manufacturing process that achieves excellent results.

Perfume bottle holders redesigned with TECHNYL® STAR achieved both aesthetic appeal and functional integration without secondary finishing. Polymers offer superior ergonomic and tactile benefits compared to metals.

Standout Properties of Polymers vs Metals

Material Selection Strategy: Lifecycle Thinking

- Concept: Define the performance needs of your end product, not just material specs.

- Design: Use simulation to validate processability, geometry and stress points.

- Material Selection: Choose the simplest polymer that meets the brief.

- Tooling & Production: Align material choice with processing capabilities & optimal production.

- Prototyping: Validate your design and material choice with computational prototyping.

- Process Optimisation: Monitor for moulding defects, refine the process for robust manufacturing.

Following this thought process will help with using the right types of plastics for your product, refining production processes, supply chain optimisation and much more.

Conclusion

Material selection for metal replacement is a strategic decision. By focusing on what the product needs to do—not what the data sheet says—you will achieve performance, cost effectiveness, and sustainability. Glass-filled nylons, PPAs, and hybrid polymers all have their place—but the best choice is the one that’s fit for purpose.

New e-learning course!

Learn the best practices for replacing metal in your next project

The process of replacing metal with polymers isn't as straight forward as it may seem. It requires careful consideration from design to production.

To support you on this journey Ultrapolymers have collaborated with DOMO, producer of TECHNYL® polyamides, with an online course to support you in this process.