Hybrid Metal Replacement: Combining Strength & Sustainability

Simon Clegg

Business Development Manager

Ultrapolymers Ltd

Simon Clegg is a highly experienced Business Development Manager with an extensive career in the polymer industry. Specialising in delivering innovative material solutions for demanding applications, supported by a strong background of working in polymer processing. Simon combines deep product knowledge with a practical understanding of customer needs, helping businesses transition to advanced polymer technologies for improved performance, cost efficiency, and sustainability.

Why Hybrid?

Not every component can—or should—be made entirely from plastic. In some cases, the solution is a hybrid design that uses metal where strength is essential and plastic to benefit from other properties. This approach delivers the best of both worlds: structural integrity, weight reduction, corrosion resistance, and cost efficiency.

Hybrid metal replacement is gaining traction across industries, from heavy machinery to automotive, E&E, and medical devices, as manufacturers seek to optimise performance while meeting sustainability and cost targets.

Hybrid designs are ideal when:

- Mechanical properties, including fatigue resistance, ultimate tensile strength and creep resistance, are critical in certain load-bearing zones.

- Low-density materials are desirable for lightweighting. Improving the energy efficiency of cars, the ergonomics of industrial & medical equipment, and the user friendliness of home appliances.

- Cost and sustainability goals are a focus. Demanding a streamlined manufacturing process that reduces carbon footprint and costs without compromising on durability.

By combining metal and plastic, manufacturers can reduce overall part weights by up to 40%, lower CO₂ emissions through less energy-intensive processing, and simplify assembly by integrating features into moulded plastic parts.

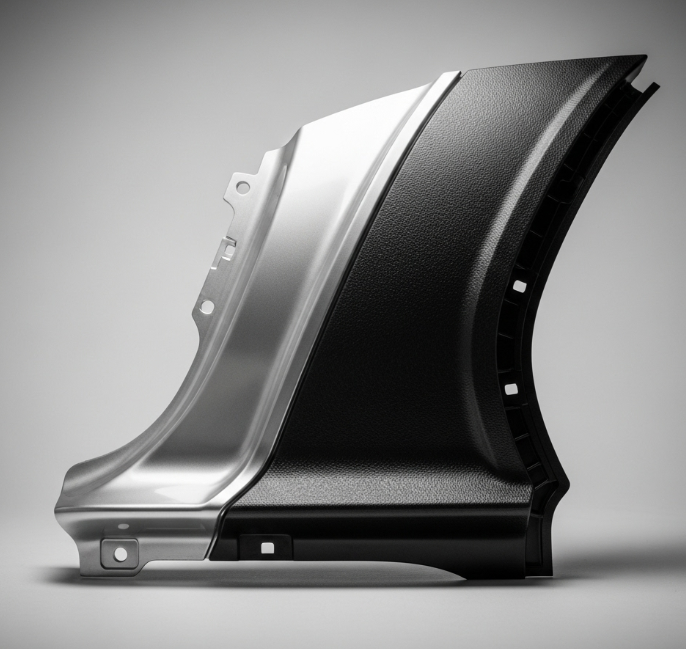

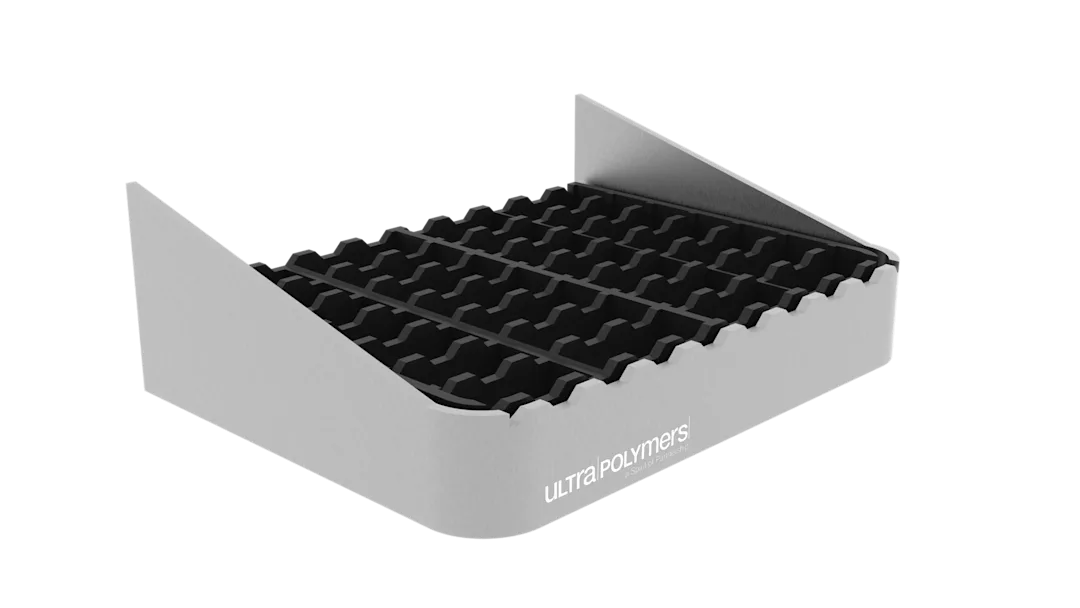

Example 1: Tractor Step

A tractor step is a perfect illustration of hybrid design. Manufacturing such a metal part involves the stamping and bending of several separate, individual components. Assembly lines then weld or bolt all of these together before applying a surface treatment. An extensive process that requires a complex assembly line of different machinery that is energy and labour-intensive.

Switching to a hybrid solution streamlines the manufacturing process significantly, reducing the energy consumption, carbon footprint and overall cost per product.

- Metal Frame: Provides the rigidity and load-bearing capability needed to support operators and withstand the wear and tear that comes with working in harsh outdoor conditions.

- Plastic Grille: Replaces the metal tread with a high-performance polymer insert, reducing weight and minimising corrosion risk while maintaining slip resistance and durability.

Benefits of this hybrid approach:

- Lightweighting: Significant weight reduction compared to an all-metal step.

- Corrosion Resistance: Plastic grille resists rust and chemical exposure from mud, fertilisers, and cleaning agents.

- Cost Efficiency: Lower material and processing costs, with simplified manufacturing.

- Design Flexibility: Plastic allows for integrated anti-slip features and easy customisation.

Example 2: Electric Motor Housing

Electric motors require a rigid structure for alignment and heat dissipation properties, and so have always been made of metal. Manufacturing requires the production of multiple components with several machining steps. Followed by surface treatment and assembly operations to integrate mounting points and cable guides. All before an assembly line or even the consumer puts the end product together.

This process is time-consuming, energy-intensive, and costly. Switching to a hybrid solution can offer great benefits.

- Metal Core: Retains the required thermal dissipation properties. Maintains dimensional stability for bearings and rotor alignment, ensuring precise operation and long-term durability.

- Plastic Outer Housing: Provides electrical insulation, reduces weight, and integrates features such as cable routing and mounting points without secondary operations.

Benefits of this hybrid approach:

- Lightweighting: Significant weight reduction improves energy efficiency and ease of handling.

- Noise & Vibration Damping: Polymers absorb vibration better than metals, reducing operational noise.

- Cost Efficiency: Eliminates secondary finishing processes and reduces assembly complexity.

- Safety: Plastic housings offer inherent electrical insulation, improving user safety.

Example 3: Medical Mobility Aid

Mobility aids such as walkers or crutches have traditionally relied on all-metal construction for strength, but this results in heavy, uncomfortable products. Manufacturing these products is intensive, involving extrusion of metal tubing, cutting, bending, welding, and finishing.

A hybrid approach combines the strength of metal with the ergonomic and hygienic benefits of polymers, creating a product that is lighter, safer, and more user-friendly.

- Metal Tubes: Deliver the structural strength needed for stability and intensive load-bearing.

- Plastic Frame, Handles and Connectors: Improve ergonomics, reduce weight, and allow for antimicrobial additives for hygiene.

Benefits of this hybrid approach:

- Lightweighting: Easier for users to lift and manoeuvre, reducing fatigue and making them more accessible for all user types.

- Comfort & Haptics: Plastic grips provide a better tactile feel and are thermally insulating, enhancing patient comfort.

- Hygiene: Antimicrobial additives in polymers minimise the buildup of biofilms that are notoriously difficult to clean on metal, thus improving cleanliness and patient safety.

- Customisation: Plastic components allow for ergonomic shaping and branding options, helping to make mobility aids more aesthetically appealing to users whilst being cost-effective to produce.

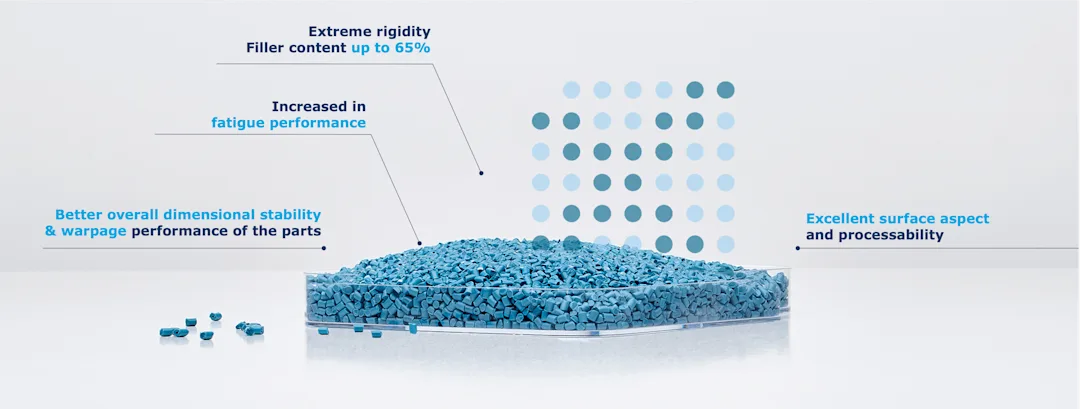

Material Selection for Hybrid Components

When designing hybrid parts, consider:

- Metal for load-bearing zones: Steel or aluminium for frames and brackets.

- Polymers for secondary structures: Glass-filled polyamides (PA6, PA66) for inserts, offering stiffness, impact resistance, and chemical durability.

- Joining Techniques: Overmoulding, integrated snap fit mechanisms, or adhesive bonding to ensure robust integration.

DOMO’s TECHNYL® MAX range is engineered for hybrid applications with excellent flow properties for complex geometries, optimised chemistry for bonding to metal, and high levels of reinforcement for optimal mechanical properties.

Design Considerations

Plastic isn't a drop-in solution for metal; you must optimise the design for manufacture, mechanical performance and functionality. There are many things to consider, but some are:

- Geometry: Incorporate ribs and structural features in plastic to recover stiffness.

- Simulation: Use mould flow and FEA tools to validate bonding and stress distribution.

- Surface Prep: Treat metal inserts for optimal adhesion during overmoulding.

Optimise your design by working in collaboration with your tool maker, injection moulder, and material supplier. The input from these experts will ensure your product meets your performance standards with a robust manufacturing process.

Conclusion

Hybrid metal replacement is a practical, cost-effective solution for industries where full plastic conversion isn’t feasible. The hybrid strategy brings competitive advantages to your product, including:

- Performance Optimisation: Using metal only where its properties are essential ensures product durability and reliability.

- Sustainability: Minimising overall metal content and energy-intensive processes reduces the product's carbon footprint and improves recycling at the end of life.

- Ergonomics: Lighter components improve handling and reduce operator fatigue, making products accessible and inclusive for all user types.

By strategically combining materials—metal for strength, plastic for flexibility and weight savings—manufacturers can deliver durable, efficient, and sustainable products without compromise.

DOMO’s TECHNYL® polyamides make this possible, offering the performance, processability, and bonding capability needed for next-generation hybrid designs.

New e-learning course!

Learn the best practices for replacing metal in your next project

The process of replacing metal with polymers isn't as straight forward as it may seem. It requires careful consideration from design to production.

To support you on this journey Ultrapolymers have collaborated with DOMO, producer of TECHNYL® polyamides, with an online course to support you in this process.