Even as Oceanworks was still getting its “sea legs” back in 2018, the company was ambitiously pursuing strategic relationships with large, global brands. At Outdoor Retailer, the largest trade show for the outdoor sporting goods industry, The North Face introduced Oceanworks to The YKK Fastening Products Group.

YKK has long been a leader in the landscape of sustainable apparel and fashion. In fact, YKK Group’s Environmental Pledge, signed in 1994, names “‘harmony with the environment" as the highest priority of its business activities. Oceanworks and YKK immediately aligned on vision and began identifying potential avenues for collaboration.

Coil zipper taping quickly became an area of focus. Zipper taping is the material located to the left and right of the actual zipper. This material is what’s actually sewn into the garment or bag, versus the zipper itself.

Despite being a relatively overlooked aspect of garment and baggage construction, it’s a crucial element of successful zipper functionality. Already a dominant supplier for this market, YKK had the capabilities and relationships to “Sea Plastic Differently,” and Oceanworks was ready to help them do so.

The Challenge

YKK required a very high-quality fiber for manufacturing the zipper taping. For a successful transition to ocean plastics, the recycled material needed to match the standards and demands of the virgin material currently in use.

Luckily, the Oceanworks network included a supplier who was not only geographically close to YKK’s manufacturing facilities, but also had well-developed chain-of-custody processes. Most importantly, their PET fiber was superb and easily met the high standards YKK demanded.

The Process

First, YKK determined the denier and filament weights needed to properly qualify the material from the supplier that Oceanworks had identified from its network. From there, YKK underwent an intensive research and development phase, demanding strict quality controls and assuring that products manufactured with this material would pass the tests of time and heavy usage, as there is no part of a garment or baggage that undergoes as much stress and utilisation as the zipper area.

With zippers being one of the biggest points of failure for products, there is no appetite for compromising quality, ease of use, or durability. Manufacturers wouldn’t take a chance on a zipper that could jeopardise their brand reputation or customer experience.

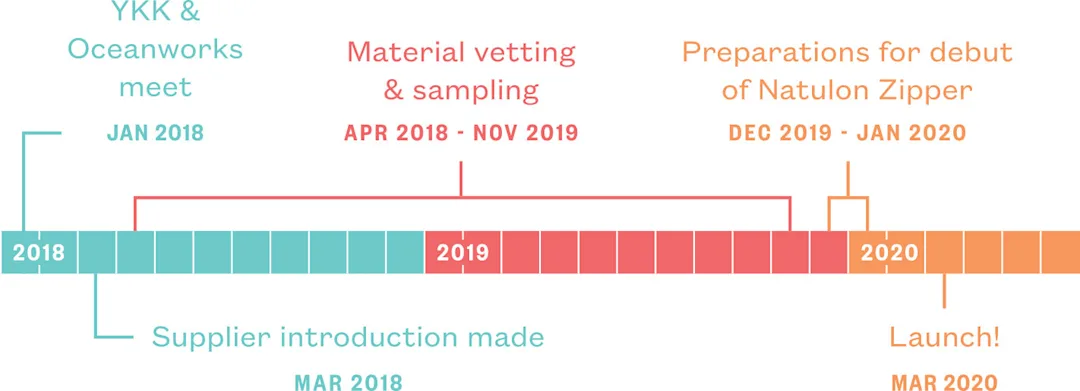

After a rigorous two-year quality assurance process of vetting the recycled ocean plastic material and perfecting the manufacturing processes, YKK was ready to debut the NATULON Ocean Zipper.

Timeline

The Results

By offering a zipper that features recycled material, YKK enables thousands of brands around the world to increase the percentage of their products featuring recycled ocean plastic. Each individual zipper makes a positive environmental impact, and these brands sell large volumes of products with zippers, adding up to some impressive impacts very quickly.

YKK and Oceanworks have seen an outpouring of requests for the NATULON Zipper Collection, illustrating that there is a large and still unmet demand for components with environmental benefits in high-volume industries. Sustainability is a truly powerful message that brands want to invest in and spread.

Despite the many global challenges apparel designers and brands face, they trust the quality of YKK products, and they value the ease of access of the Oceanworks global material marketplace for recycled ocean plastic material and components.