Bicycles have been around for over two centuries. While the fundamentals are unchanged, there remains an endless commitment to innovation and iteration among the many manufacturers around the globe. Road bikes get faster and lighter while mountain bikes get more air and absorb more impact. But innovation isn’t always about maximizing performance… sometimes it’s just about having fun.

Under the [beach] umbrella of bicycles sits the ever-iconic beach-cruiser. Beach-cruiser bikes are all about style and flair while still providing a reliable and efficient form of transportation to adults and children alike. Influenced by the beach and surfing lifestyle of Southern California, Germans Benno Baenziger and Jeano Erforth founded Electra in 1993 to reinvent this classic bike and introduce a new generation to the joys of cruising.

Electra is “inspired by the artistry of our culture and the details that surround us. They started the company with the idea that they could always do better, because innovation is what ultimately sets us apart.” With sandy shores and ocean waves as a backdrop, their interest in reducing ocean pollution was an obvious synergy with their entire mindset and approach.

Now part of the Trek family of bicycles, the brand is ready to shake things up further. Long committed to environmental stewardship, Electra is now pushing the boundaries further by partnering with Next Wave Plastics and Oceanworks to use recycled ocean plastic for a plethora of parts and accessories.

Telling the Ocean Plastic Story

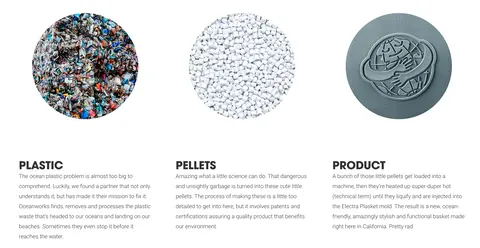

Electra chose to focus on ocean-bound plastic for their beach cruiser. This category of ocean plastic which is defined as discarded plastic waste collected within 50 km of the shoreline, is in many ways paramount to solving the crisis and matches the beach ethos of the brand seamlessly. As a brand that espouses a coastal lifestyle, the company connected with the importance of keeping beaches, shorelines, and neighboring areas free of plastic waste as it impacts the entire ecosystem.

Brands and consumers alike are surprised—and sometimes disappointed—that “ocean plastic” isn’t exclusively plastic literally pulled from the ocean, but rather a mixture of these materials bundled together with land based plastic imminently at risk of entering the oceans and environments; soon becoming part of the proverbial tsunami of plastic flooding our planet. While removing plastic from the ocean is an essential component to protecting and repairing the planet’s waters, it’s just as important to prevent additional plastic from making its way there.

This narrative resonated with Electra and they wanted—and succeeded—in articulating this more nuanced story as part of the environmental and social benefits of their innovative use of ocean plastic.

What better way to bring it all home than turn plastic destined to pollute the beach into a product people use to get there and enjoy the natural beauty they’re helping preserve!

The Challenge

Electra had ambitious plans to incorporate ocean-bound plastic into its manufacturing processes, with its sights set on accessories (and accessories are a big part of the cruiser bike culture). The variety and volume of this endeavor required a large amount of material to ramp things up and produce them at scale.

Electra needed a reliable source of authentic material that stood up to their needs. They needed resins capable of working with their demanding injection molding process and a steady pipeline of capacity to meet demand.

The Process

The team focused first on a core element of the beach cruiser lifestyle: carting everything you’d need for a day at the beach on your bike. The flat coastline roads and ability to always find a parking spot make beach cruisers a particularly attractive mode of transportation for a day by the waves.

Thus came the inspiration for the Plasket, which would be Electra’s flagship ocean plastic accessory. Electra was already the leading supplier of bike baskets to independent bike dealers, so this product would have a reach far beyond Electra’s line of cruisers and e-bikes.

This tote attaches via an included bracket to the bike’s handlebars or rear storage rack and is versatile enough to be comfortable carrying it by hand once the pavement ends and the sand takes over. From burritos and cold drinks to hats, towels, and sunscreen, bicyclists can bring along what they need and bring it home when they’re done. It’s also convenient for quick shopping trips or bringing things over to a friend’s house.

Following in the tire tracks of other successful product developments with local manufacturing corporation, Medway Plastics, Oceanworks material was suggested as a perfect option for this upcoming tote being developed.

The Results

Electra debuted the Plasket in 2021 in four fun colors (guava orange, shell white, lunar grey, and mint green) and was met with stellar reviews for its style, functionality, and carrying capacity of 27 liters weight tolerance of 11 pounds. It’s positioned as a great summer purchase for bicyclists looking to make the most of their rides while doing the planet a solid.

Using the tagline “Carry more. Leave less.”, the marketing campaign is focused on two key elements of the Plasket; its versatility as a fun and fashionable bike accessory along with its significant environmental impact. Each Plasket is made from one pound of recycled ocean-bound plastic, and the environmental benefits of that add up quickly. The initial production run is saving 3,645 cubic feet of landfill space and 2.2 tonnes of CO₂ emissions.