Life can oftentimes be a whirlwind. In the melee, people are constantly misplacing their keys, forgetting where they left their wallets, and leaving behind their cell phones. Call it clumsy, forgetful, or distracted--the reason is beside the point: when you have lost your essential items, you just want to be reunited with them as quickly as possible.

Chipolo has the solution. Using Bluetooth technology placed inside plastic-encased transponders, Chipolo leverages technology to cut down on the time people spend looking for their missing objects, resulting in less stress and prompt reunification. Instead of spending precious time searching for items or devices, customers can open the Chipolo app and view their item’s last known location, or trigger an audio alert on the Chipolo tracker for a 21st-century “Marco Polo” experience.

With an environmentally-conscious approach baked into the corporate DNA of this Slovenian company, founded in 2013, Chipolo set out to create an innovative, sustainable product using ocean plastic materials.

The Challenge

For Chipolo’s products, there are no viable alternatives to plastic. Plastic is able to withstand the rigors of daily use while still remaining lightweight and soft to the touch. At the same time, Chipolo recognizes the dangers and damage that plastic poses to the environment, so they set their sights on creating a new line of Chipolo devices made from recycled plastic instead.

Creating a version of their flagship product made from recycled plastic meant finding an alternative feedstock to virgin plastic that still met all their requirements and quality demands. To meet their goal of limiting the creation of new, petroleum-based plastic, ocean plastic seemed like a win-win solution, as it not only limited their reliance on virgin plastic but also delivered the additional benefit of reducing plastic pollution in our waters.

To meet their goal of uncompromising durability and an excellent customer experience, Chipolo needed to determine which type of ocean plastic resin would work in their existing manufacturing processes. Chipolo was already using engineered polymers blends; however, they needed the support of a trusted partner to help them identify the best materials for their needs and then deliver reliable recycled plastic in the quantities they required and within the timeline they were seeking. This is when Chipolo turned to Oceanworks.

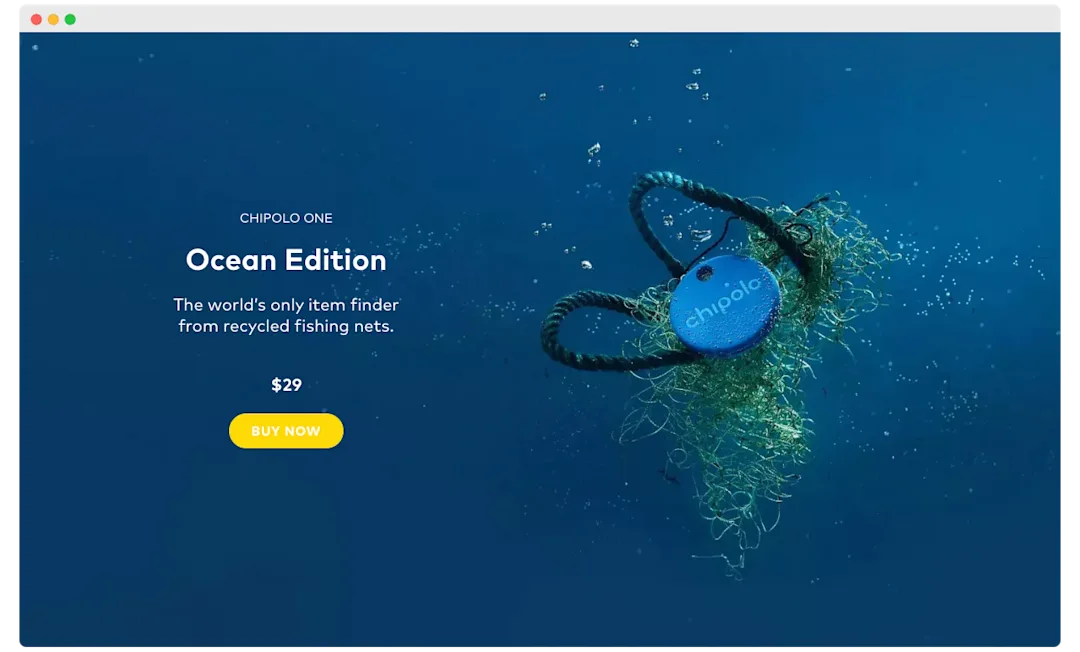

"In collaboration with Oceanworks we launched Chipolo ONE Ocean Edition, the world's only Bluetooth item finder made from recycled fishing nets. Oceanworks team was really nice to work with, very helpful with providing the desired recycled materials and offered great support in terms of visuals for marketing purposes." - Nika Kramžar, CMO, Chipolo

The Process

Chipolo contacted Oceanworks and communicated what they were looking for. After a week of discussions, the Chipolo team determined that using plastic derived from recycled fishing nets, trawls and ropes was a promising option. Not only was the polypropylene plastic a good match, but the benefit of reducing the volume of discarded fishing nets threatening sea life and marine ecosystems made it even more attractive.

Chiopolo ordered samples via the Oceanworks Marketplace and put the material through paces, running some test production runs with this recycled ocean plastic. After overcoming a few assembly roadblocks, the switch was seamless, and Chipolo quickly transitioned to fully productizing their new offering, the Chipolo One Ocean Edition.

Marketing and messaging were developed in collaboration with Oceanworks, leveraging Oceanworks-provided media assets, and the Ocean Edition launched to much acclaim.

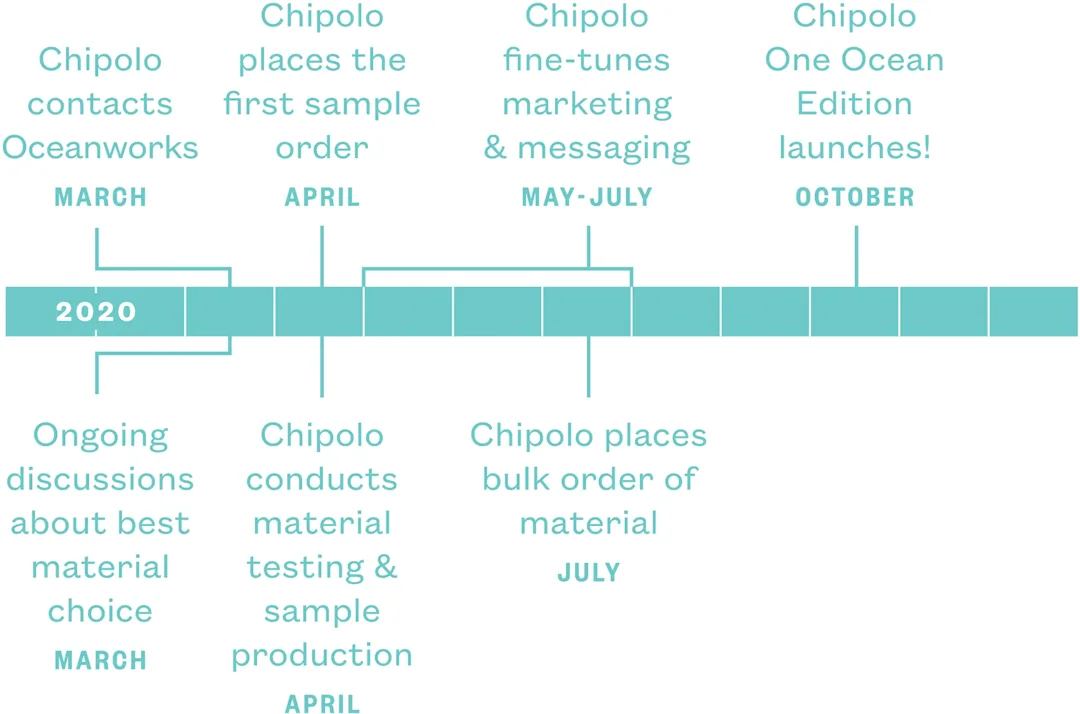

Timeline

Chipolo’s commitment to incorporating recycled ocean plastic into their product line paid off with an accelerated rollout. Their rapid progression from initial inquiries to shipping a product manufactured with recycled ocean plastic is an impressive endorsement of the versatility and viability of the material and the time-savings and convenience that the Oceanworks Marketplace can provide.

Chipolo's ability to progress from a strategic decision in the late winter to a product release in the early fall is truly impressive, particularly when considering that this entire process occurred during a global health pandemic that disrupted daily lives, work behaviors, and the entire supply chain. Many organizations might have shelved their plans to introduce a game-changing product in these market conditions, but Chipolo stuck to its vision and--with the help of Oceanworks-- made it all happen.

"Chipolo had a vision and determination to make a splash in their market and I could not be more proud of the Oceanworks team for moving fast and delivering for our customers." - Rob Ianelli, President, Oceanworks

The Results

The Chipolo One Ocean Edition is an extension of Chipolo’s other sustainable product decisions. For example, Chipolo products feature replaceable batteries, which--although they are more expensive and difficult to manufacture--ensure that customers can use their products for a lifetime while simultaneously avoiding plastic waste from products that must ultimately be replaced. Chipolo has also introduced a free recycling program for their original line of Chipolo devices that did not have the replaceable battery option.

For the Chipolo One Ocean Edition, Chipolo reinforced their sustainability commitment by committing to donate $1 for each Ocean Edition purchase, with the funds going to marine cleanup efforts. Now consumers are not only making an environmentally responsible choice when they purchase Chipolo One Ocean Edition products, but they’re also directly supporting further removal of marine debris from our oceans and waterways.

The Chipolo One Ocean Edition has not only been a stunning success in terms of product development and a bold commitment to sustainability; it has also garnered Chipolo a barrage of positive press that should only serve to further boost sales and spread their message to a wider audience, including being featured in Forbes and Apple Insider.