Compounding

Polymers are incredibly versatile materials with a broad scope of uses, and this is one reason why they are used widely in the production of numerous compounds.

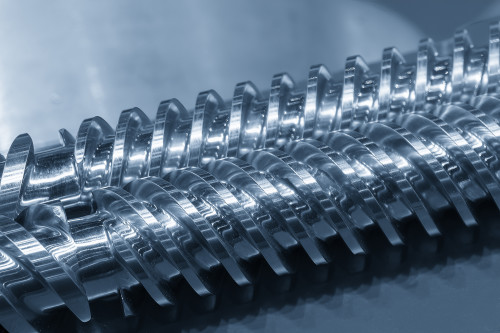

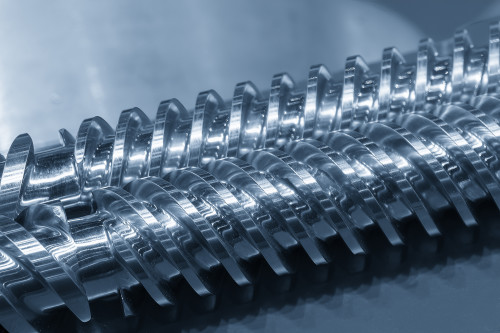

Plastics compounding is the process of melt blending polymers together with other additives. This process optimises the physical, thermal, electrical or aesthetic characteristics of the polymer. The final product is called a compound.

Additives can include pigments, fillers (eg glass fibres or minerals), additives e.g. UV protection, Flame retardants etc.

With applications as varied as hot melt adhesives, purging, masterbatches and polymer compounds, the Ultrapolymers range of polymers can support you in developing the formulation you require.

Market segments

Adhesives

The use of polymers in adhesives is one of the oldest known applications for polymers where, in the earliest times, natural polymers were used. In modern times this has evolved to include the use of sophisticated polymers and additives to create a broad range of adhesives.

Applications

- Hot Melt Adhesives (HMA)

- Two Pack Adhesives

- Sealants

- Structural Adhesives

Adhesives

The use of polymers in adhesives is one of the oldest known applications for polymers where, in the earliest times, natural polymers were used. In modern times this has evolved to include the use of sophisticated polymers and additives to create a broad range of adhesives.

Applications

- Hot Melt Adhesives (HMA)

- Two Pack Adhesives

- Sealants

- Structural Adhesives

General

Polymer compounding allows you to make bespoke alloys of materials to suit the demands of your product. With access to a vast array of fillers whether it be fibres or minerals, Ultrapolymers can help you fine tune characteristics such as strength, thermal stability and conductivity to give you a customised solution. Compounding also opens up avenues for sustainable materials through use of recycled content, renewable feedstocks, and fillers to optimise your product's longevity.

Applications

- Bespoke polymer compounds suitable for any market including automotive

- Healthcare and electronics

General

Polymer compounding allows you to make bespoke alloys of materials to suit the demands of your product. With access to a vast array of fillers whether it be fibres or minerals, Ultrapolymers can help you fine tune characteristics such as strength, thermal stability and conductivity to give you a customised solution. Compounding also opens up avenues for sustainable materials through use of recycled content, renewable feedstocks, and fillers to optimise your product's longevity.

Applications

- Bespoke polymer compounds suitable for any market including automotive

- Healthcare and electronics

Masterbatch

One of the most common ways to differentiate a plastic product is the use of a colourant, a cost-effective and easy-to-use solution is by using a masterbatch. A further key use of masterbatches can also be to modify a material's property or introduce a performance-enhancing additive.

Ultrapolymers offer a range of materials ideally suited for the production of masterbatches and property modification.

Applications

- Colour masterbatches

- Property Modifiers

- Additive carriers

Masterbatch

One of the most common ways to differentiate a plastic product is the use of a colourant, a cost-effective and easy-to-use solution is by using a masterbatch. A further key use of masterbatches can also be to modify a material's property or introduce a performance-enhancing additive.

Ultrapolymers offer a range of materials ideally suited for the production of masterbatches and property modification.

Applications

- Colour masterbatches

- Property Modifiers

- Additive carriers