PVC-Free Polymer Solutions

for Medical Tubing

PVC (Polyvinyl Chloride) has been the go-to polymer for flexible tubing for many years. The material has a strong history of use thanks to its chemical stability, clarity and transparency, biocompatibility, flexibility, resistance to chemical stress cracking, excellent bond-ability and low cost.

PVC's excellent balance of properties is thanks to the addition of plasticisers that enhances the material's flexibility, transparency and durability. These plasticisers contain phthalates, a group of chemicals that is of increasing concern due to their impact on aspects of our health.

This is driving the need for PVC alternatives, especially in the medical industry where patients can be subject to prolonged exposure to flexible tubing through renal therapy, respiratory aid, urology procedures, enteral feeding, IV infusions, perfusions and exposure to medical packaging.

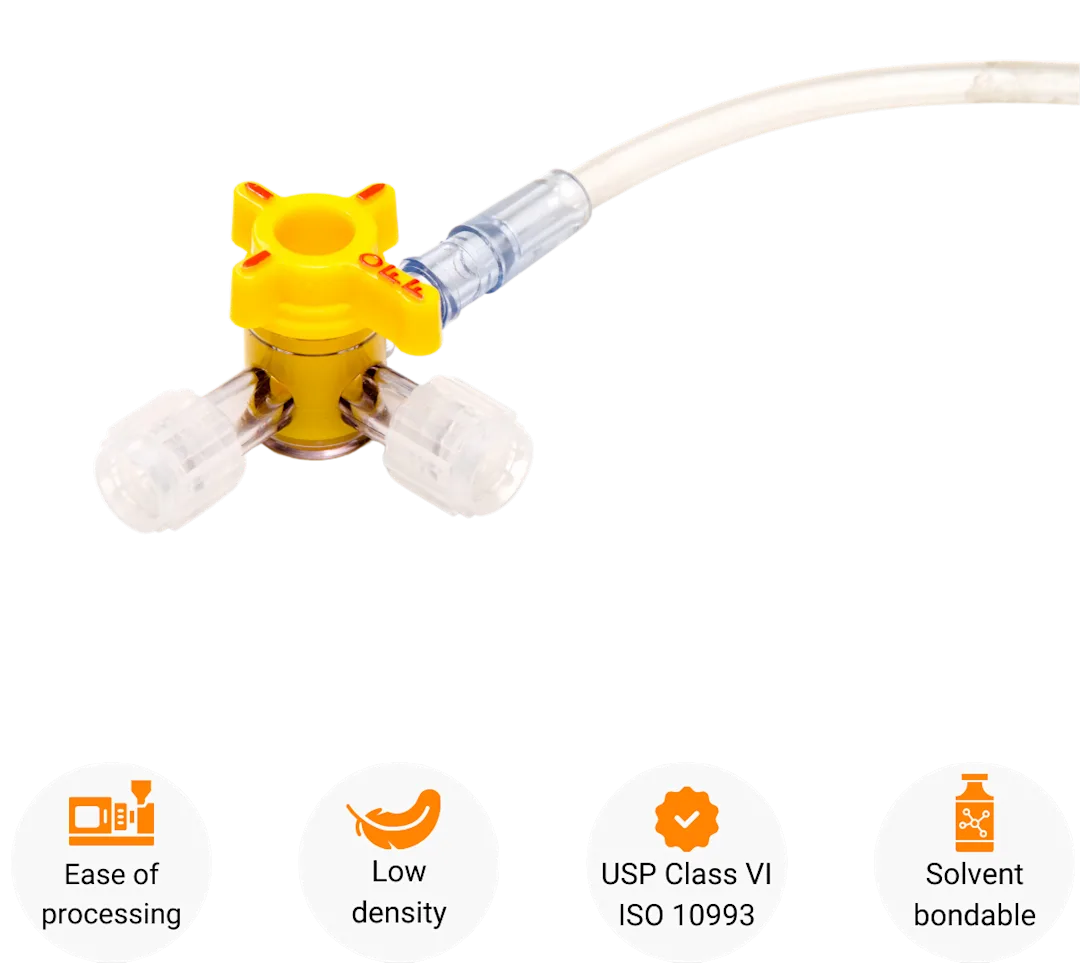

Styroflex® S-TPE

INEOS-Styrolution is the global leader in styrenics and the second largest producer of ABS. Offering a broad range of styrenic copolymers and compounds from reinforced, high rigidity ABS to crystal clear MABS and flexible S-TPEs ideal for flexible tubing, you can find all that you need for your entire product assembly. INEOS-Styrolution's offer to the healthcare and diagnostics market is 3-fold and is targeted to the needs and risks of each individual application.

Styroflex® from INEOS-Styrolution is a styrenic based thermoplastic elastomer, in short S-TPE, that exhibits:

- good processability with minimal water absorption thus requiring no drying (provided adequate storage etc.)

- rubber-like mechanics with outstanding toughness, tear and perforation resistance

- high oxygen and water vapour permeability

- low density lightweighting your products and potentially reducing material costs

- great transparency and low yellowness index

- high polarity facilitating great combatability and bonding properties to other styrenics and polyolefins

- medical compliance to USP Class VI and ISO 10993

Purell® PP Blend

LyondellBasell is the world's largest producer of polypropylene (PP) and polypropylene compounds (PPC), as well as a top worldwide producer of polyethylene (PE). Offering exceptional service and product quality, based on more than 40 years of interaction with customers using polyolefins in healthcare applications. As the market leader in polyolefin-based healthcare applications, LyondellBasell has built a strong reputation of excellence in this field.

Purell® KT MR 07 from LyondellBasell is a metallocene based polybutene-1 (PB-1) that can be used in conjunction with a random copolymer polypropylene, such as Purell® SP170G, in different concentrations to achieve the desired softness and flexibility characteristics.

- Chlorine and plasticiser free for easy recycling or energy recovery via incineration.

- Low oligomer content and low extractables.

- Excellent chemical inertness and chemical resistance.

- Good kink resistance and excellent flexibility.

- Suitable for injection moulding, blow moulding, extrusion and film packaging.

Purell®, LyondellBasell's healthcare brand, delivers on reliability, confidence, experience and innovation, equipped with a notification of change period of 2 years, and compliance with USP Class VI, EU Pharmacopeia, ISO 10993 and drug master file (DMF) listing.

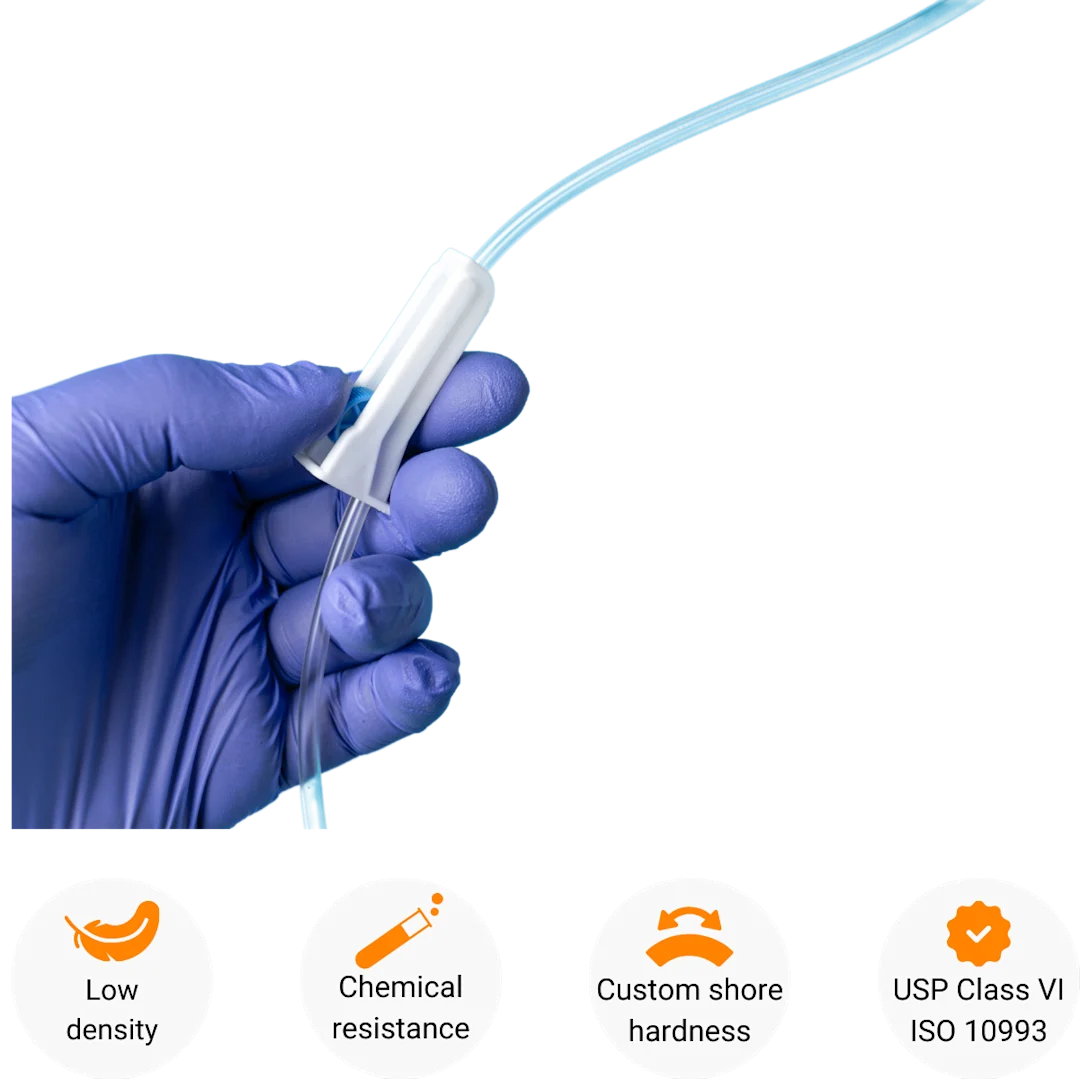

MARFRAN.MED TPE

Marfran.MED is a range of transparent and coloured TPE compounds dedicated to the medical and pharmaceutical industry. With a strong, in-house R&D facility, the Italian company possess the capability to develop and certify tailor-made grades for your specific product requirements.

The Marfran.MED materials are produced in a state-of-the-art clean room environment in accordance with ISO 9001 and ISO 13485. All materials carry ISO 10993, EU Pharmacopeia and USP Class VI certifications on the final compound. With this, comes a service package that includes a notification of change policy, sterilisation testing data using the most common methods and the availability of extensive technical data.

The Marfran.MED compounds exist in a wide range of hardnesses and are designed for different processing methods. The possibility of anti-microbial additivation in any of the compounds is also part of the extensive product offer.

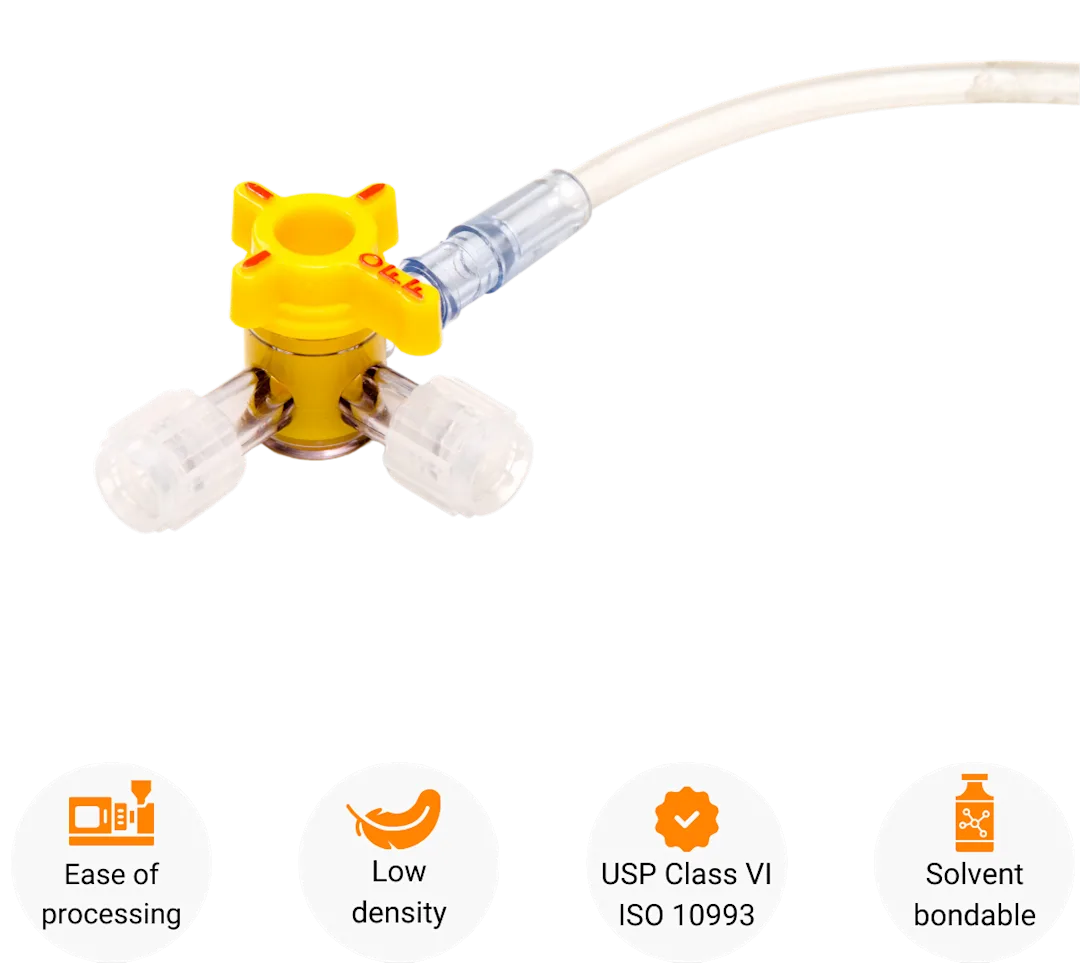

Styroflex® S-TPE

INEOS-Styrolution is the global leader in styrenics and the second largest producer of ABS. Offering a broad range of styrenic copolymers and compounds from reinforced, high rigidity ABS to crystal clear MABS and flexible S-TPEs ideal for flexible tubing, you can find all that you need for your entire product assembly. INEOS-Styrolution's offer to the healthcare and diagnostics market is 3-fold and is targeted to the needs and risks of each individual application.

Styroflex® from INEOS-Styrolution is a styrenic based thermoplastic elastomer, in short S-TPE, that exhibits:

- good processability with minimal water absorption thus requiring no drying*

- rubber-like mechanics with outstanding toughness, tear and perforation resistance

- high oxygen and water vapour permeability

- low density lightweighting your products and potentially reducing material costs

- great transparency and low yellowness index

- high polarity facilitating great combatability and bonding properties to other styrenics and polyolefins

- medical compliance to USP Class VI and ISO 10993

Purell® PP Blend

LyondellBasell is the world's largest producer of polypropylene (PP) and polypropylene compounds (PPC), as well as a top worldwide producer of polyethylene (PE). Offering exceptional service and product quality, based on more than 40 years of interaction with customers using polyolefins in healthcare applications. As the market leader in polyolefin-based healthcare applications, LyondellBasell has built a strong reputation of excellence in this field.

Purell® KT MR 07 from LyondellBasell is a metallocene based polybutene-1 (PB-1) that can be used in conjunction with a random copolymer polypropylene, such as Purell® SP170G, in different concentrations to achieve the desired softness and flexibility characteristics.

- Chlorine and plasticiser free for easy recycling or energy recovery via incineration.

- Low oligomer content and low extractables.

- Excellent chemical inertness and chemical resistance.

- Good kink resistance and excellent flexibility.

- Suitable for injection moulding, blow moulding, extrusion and film packaging.

Purell® , LyondellBasell's healthcare brand, delivers on reliability, confidence, experience and innovation, equipped with a notification of change period of 2 years, and compliance with USP Class VI, EU Pharmacopeia, ISO 10993 and drug master file (DMF) listing.

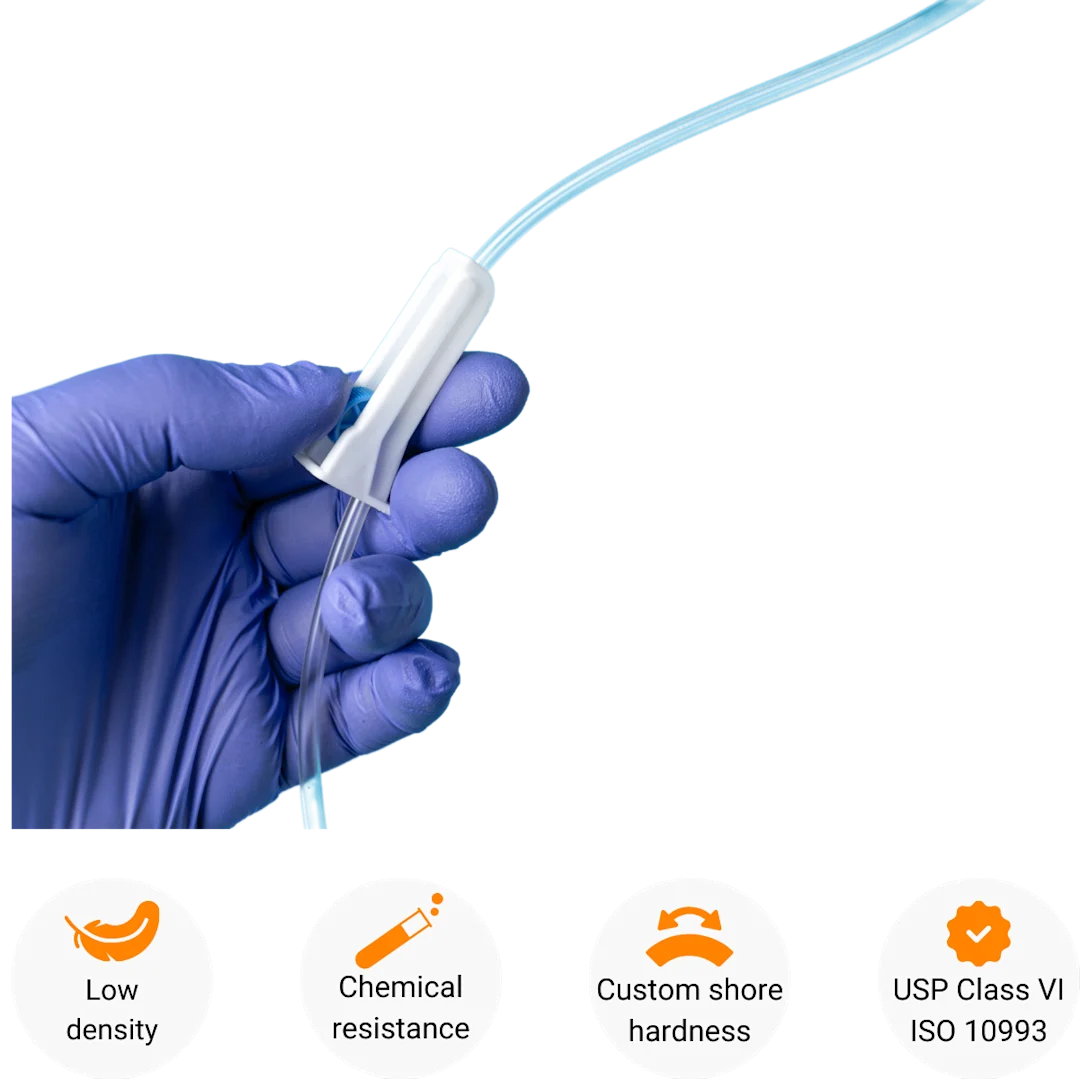

MARFRAN.MED TPE

Marfran.MED is a range of transparent and coloured TPE compounds dedicated to the medical and pharmaceutical industry. With a strong, in-house R&D facility, the Italian company possess the capability to develop and certify tailor-made grades for your specific product requirements.

The Marfran.MED materials are produced in a state-of-the-art clean room environment in accordance with ISO 9001 and ISO 13485. All materials carry ISO 10993, EU Pharmacopeia and USP Class VI certifications on the final compound. With this, comes a service package that includes a notification of change policy, sterilisation testing data using the most common methods and the availability of extensive technical data.

The Marfran.MED compounds exist in a wide range of hardnesses and are designed for different processing methods, with solvent bondable options available as well. The possibility of anti-microbial additivation in any of the compounds is also part of the extensive product offer.

Ultrapolymers' Healthcare Promise

Design Support

Experienced technical and sales team to support projects from design to production

Technical Support

Knowledgeable technical team to partner with clients in optimising their production

Leading Materials

Polymer solutions from leading suppliers such as LyondellBasell, INEOS Styrolution and BASF

Own Compounding

ISO 13485 certified compounding plant offering bespoke one bag polymer solutions

Sustainable Solutions

Broad range of sustainable solutions from some of the polymer industry leaders

Logistics Network

Extensive network of warehouses and hauliers to support local stockholding and security of supply

Innovating Healthcare Together

Navigating the Product Lifecycle for a Sustainable Future in Healthcare

The Innovating Healthcare Together event, hosted by Ultrapolymers brought suppliers, industry leaders and our customers to one location to discuss the key trends and challenges facing production and development in the healthcare market. Key moments were captured throughout the event and are now available for you to explore. From mould design optimisation to industry leading plastics, and the latest technology in injection moulding, our speakers share insightful knowledge on how to make healthcare better for the planet.