Top brands around the world seal their spirits and wines with Guala Closures products, preserving the purity and freshness of each bottle’s contents. These closures offer different performances according to a brand’s specific needs and comply with regulations and standards in every country where they are used.

Guala Closures Group was founded in 1954 and is an undisputed market leader in beverage closures. Headquartered in Italy, the Group manufactures over 20 billion closures annually for a global customer base, employing over 4,700 employees across 30 production facilities on five continents.

As the beverage industry shifts, like many others, towards greater sustainability, Guala Closures has sought different ways to help its clients limit their environmental footprint and create innovative solutions. Maximizing the use of recycled materials is a clear win. Finding more responsible materials for the billions of bottles it tops and seals each year was an obvious path to creating a major impact.

The Group set a goal of using 35% recycled material worldwide by 2025. And while each closure may only use a little plastic, the aggregate volume is substantial. This means even a fraction of the total volume shifting to recycled content makes a big, measurable difference.

Guala Closures aims to lead the way in the market by proposing the most innovative and sustainable solutions which are suitable for the highly regulated, global spirits and wine markets.

Being a long-term packaging partner of most top spirits and wine brands worldwide, Guala Closures has established a privileged relationship with its clients, working hand in hand with their teams to create advanced solutions. Additionally, the company supports its clients to achieve their ambitious CSR objectives, which include plastic reduction targets in their packaging. Guala Closures’ close customer partnerships enable them to anticipate both clients' and customers' expectations, and offer packaging that meets their needs with performance and style.

Inspiration

Guala Closures’ commitment to sustainability is embodied in its new design guidelines, which emphasizes four key design pillars:

- Design to Reduce - eliminating any unnecessary materials from products and production processes;

- Design to Fade - relying when possible on materials that naturally biodegrade over time while using a minimal number of components;

- Design to Revive -increasing the recovery and recycling of closure materials;

- Design to Change - abandoning virgin and single-use resources by shifting to recycled and recyclable materials.

Guala Closures came to Oceanworks in search of ocean plastic that could meet their sustainability commitment and high-performance needs. While they could have used any recycled plastic, the dual benefit of ocean plastic was appealing. Not only would they reduce their reliance on virgin plastic, but Guala Closures would also be participating in the reduction of plastic waste defiling waterways and oceans.

The Group had a distinct vision from day one that incorporated both practical and design aspects. Inspired by the sea creatures featured throughout the Oceanworks website, Guala Closures incorporated sea creatures into dedicated designs for the BlossomTM collection. The closures turned out beautifully, really capturing the textures and details of each scene and highlighting the premium quality of Guala Closures’ products.

The Process

After settling on an initial design, Oceanworks worked with Guala Closures to understand the stringent requirements needed to produce closures capable of withstanding the demands of the spirits industry.

Oceanworks identified the optimal recycled ocean plastic formulations and specific suppliers. Guala Closures bought samples of these plastics, running them through multiple rounds of rigorous testing. To optimize production, it has designed tailored injection tools to better fit this new feedstock, which is comprised of a 100% blend of recycled ocean plastics.

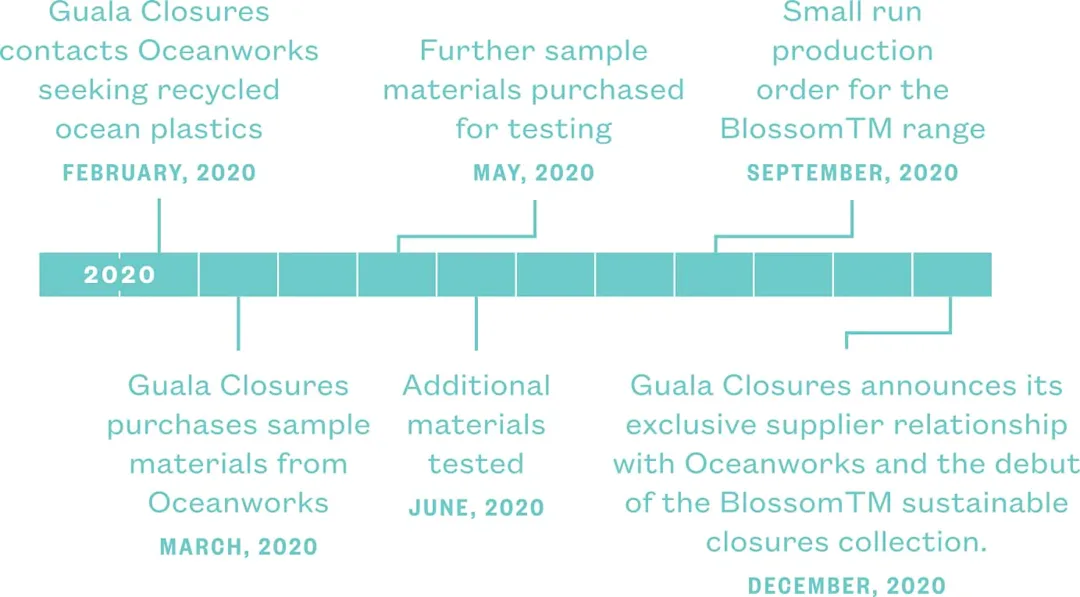

Perhaps most impressive of all, this all occurred in the middle of a global pandemic that limited personal travel and greatly disrupted international supply chains and logistics planning. Yet the project progressed from the first contact to a production launch within a single year. At the end of the process, Guala Closures and Oceanworks signed an exclusive ocean plastic supply agreement for the spirits and wine closures market.

Timeline

Results

Simply put, the Guala Closures Group is completely committed to this project, even creating new tools for injection moulding to capture the essence of sea life and translating it to an addressable market. These simple, yet aesthetically pleasing closures are just the beginning.

An exciting part of this launch was Guala Closures’ determination to use a 100% blend, meaning all plastic is Oceanworks Guaranteed ocean plastic. The fine details and textures accomplished in the tooling were superb and Oceanworks is excited to see the launch and reaction to this massive advance in sustainability-focused packaging components.

These ocean plastic closures are one of many innovations in a series of sustainability-focused, customizable closures. While Guala Closures is releasing this new solution for the T-bar range of spirit closures, additional product lines will be introduced soon. This gives more customers the opportunity to purchase these eco-friendly products and further reduce their reliance on virgin plastics.

“This important agreement strengthens the Group’s commitment toward more sustainable solutions, making our closures part of the future circular economy,” said Guala Closures’ R&D director Fulvio Bosano “The success of our sustainability strategy depends on both strong internal research and partnerships with key players such as Oceanworks.”

The Oceanworks partnership is a key milestone in turning Guala Closures’ vision into reality, turning more celebrations and libations into another opportunity to reduce ocean pollution and leverage recycled ocean plastics.