Some partnerships push companies to extend themselves, to rethink what’s possible. When this type of partnership is successful, it not only creates a mutually beneficial situation, but it can help those companies expand into new markets and pursue opportunities they’d previously not explored.

The partnership between The Sak Brand Group and Oceanworks took both organizations places they couldn’t have reached alone. And now, both parties are reaping the benefits of moving beyond their comfort zones and delivering innovative products to the market.

The relationship sparked when The Sak’s CEO and founder Mark Talucci decided he wanted the company to debut a new vision for sustainability, with ocean plastic at its core. A lifelong surfer who found his inspiration for The Sak while on vacation in Bali in the 1980s, Mark truly cares about reducing ocean pollution and reducing the carbon footprint of his firm’s products.

"The Sak Group was founded over 30 years ago with an inspiration to create timeless pieces of fashion and function. I am proud to continue the journey with Oceanworks and having The Sak Group become so deeply involved in the health and conservation of our Ocean." - Mark Talucci, CEO, The Sak Group

The Sak Brand Group started in 1989, creating handbags constructed with a strong focus on unique textured fabrications. It has grown into one of the largest lifestyle accessories companies in the country, with offices in New York City, San Francisco, China, and Indonesia.

The Sak Brand Group designs and manufactures three very distinct lifestyle accessory brands: The Sak, Sakroots, and Elliott Lucca. They sell products in more than 4,500 department stores and 850 specialty stores in 24 international markets.

The Challenge

The Sak is known for their vibrant and colorful bags, which are hand-crocheted throughout Indonesia. Color is an incredibly powerful aspect of its brand and product offering, so the Sak was uncompromising in maintaining its biggest differentiator when switching from yarns made of virgin material to yarns made of recycled ocean plastics.

Finding the right material proved to be the biggest obstacle. The Sak was seeking to work with polypropylene, but when their engagement with Oceanworks began, the Oceanworks marketplace only had a few polypropylene options, none of which were available as a yarn. Oceanworks now had its work cut out to source a material that met all of The Sak’s requirements and to take this distinctive brand into the world of recycled ocean plastics.

The Process

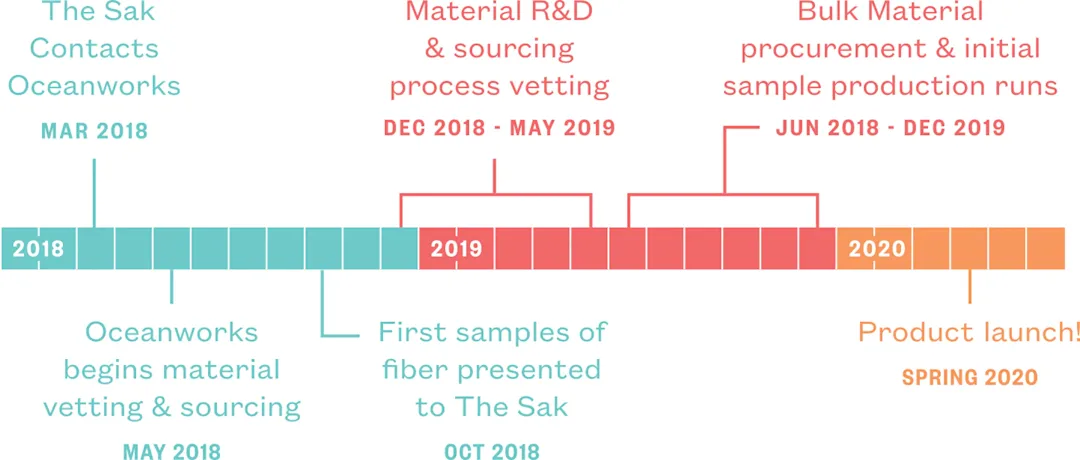

In support of The Sak’s desire to incorporate ocean plastic into their products for the first time, Oceanworks identified and recommended a polypropylene derived from reclaimed fishing gear and nets. To help facilitate The Sak’s transition to this material, Oceanworks began by gathering a full understanding of The Sak’s existing supply chain, exploring opportunities to work with The Sak’s existing yarn manufacturer. This strategy brought Oceanworks to Indonesia for meetings at the yarn manufacturer’s facilities, which is where polypropylene material is extruded into yarn for The Sak.

The Sak and Oceanworks teams discovered that extruding the recycled fishing net polypropylene into a yarn was not easy, which led to several production challenges. Oceanworks worked iteratively with The Sak to run small batches of the recycled fishing net material and improve production so The Sak could ultimately run large volumes of the material with confidence.

Timeline

The Result

After 18 months of testing and setting up production supply chains, The Sak was ready for showtime. The ReSak collection launched in Spring of 2020 to much acclaim and was one of Oceanworks’ favourite projects. Taking risks is part of both companies’ ethos, which makes the occasionally long road from inspiration to production well worth the journey.

"From day one, I knew that The Sak was determined enough to make this project happen. I couldn't be happier with the final result." -Rob Ianelli, CEO, Oceanworks

The Sak and their communications team, utilizing media assets and support from Oceanworks, crafted a beautiful and compelling narrative about the material source for its bags. The reclaimed polypropylene that Oceanworks had identified was a genuinely fitting material source, as these same nets and gear, when improperly discarded, plague the shorelines and fishing areas off the coasts of Indonesia, the very country where The Sak’s bags are hand-crocheted.

Oceanworks is thrilled to have partnered with The Sak to make its sustainable vision a reality. Successes like this are only possible when partnering organizations are equally excited and motivated to persevere through any challenges.

Oceanworks applauds The Sak for their enthusiasm and thirst for problem-solving and commends their team for launching their first ocean-based product line!