Automotive

Ultrapolymers partners with leading manufacturers such as LyondellBasell, Ineos Styrolution, Domo, Ravago, BASF, Sumitomo and Samyang and many more to offer an exceptional range of materials designed for the ever changing Automotive industry.

Ultrapolymers offers a diversified product range of materials for the automotive industry. Working in cooperation with OEMs, Tier 1, Tier 2 and other sub-moulding companies, we are able to select the most suitable solution for each specific application.

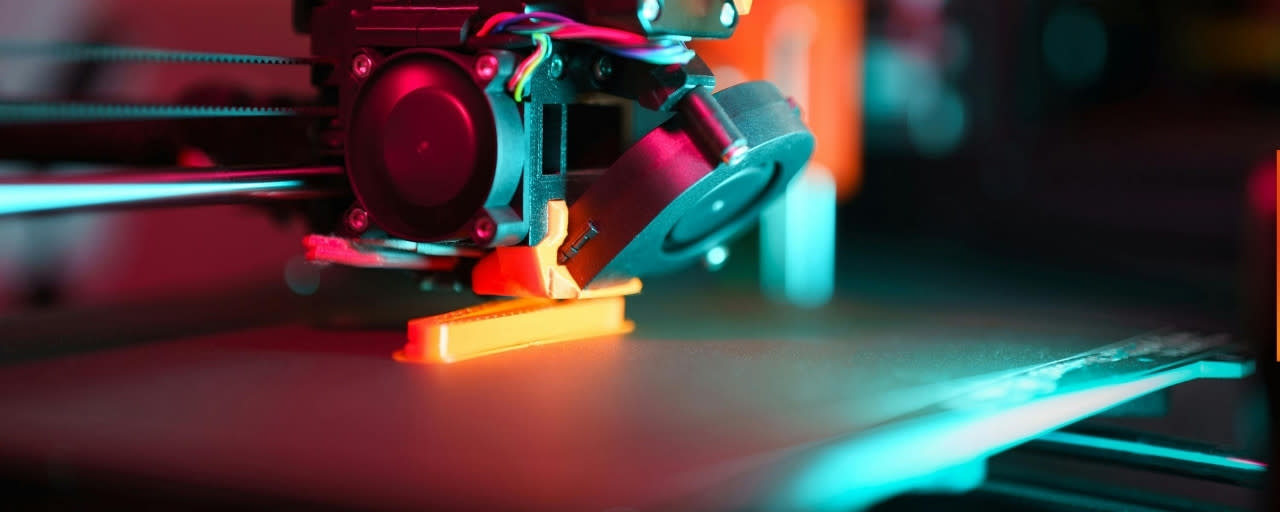

Metal Replacement Insights

Plastics in EV Chargers

Explore polymers suited for components of electric vehicle chargers

Explore this short piece of e-learning to get an introduction to the market of Electric Vehicle (EV) chargers. Learn about the different types of EV charger, the key performance requirements of different components, the materials most often used and why, and the influence of sustainability on EV chargers.

Key areas

- High quality polymers for demanding Automotive applications

- Wide range of Automotive OEM approvals from leading polymer manufacturers

- Sustainable solutions tailored to Automotive requirements

- Materials with a focus on use in BEV (Battery Electric Vehicles)

- CO2 emission reduction through weight reduction

- Local supply chain solutions to support JIT delivery

Plastics in Mobility

Learn what polymer is right for you

Do you want to understand the mobility market a bit more, the different subsegments, regulations and approvals most commonly seen, the various polymers used, in which applications and why?

Expand your knowledge with the Academy, our learning and development hub dedicated to the polymer industry. Our short course Plastics in Mobility introduces the mobility market, exploring automotive, rail, aerospace, electric vehicles and micro-mobility, the polymers used in mobility manufacturing and why.

Market segments

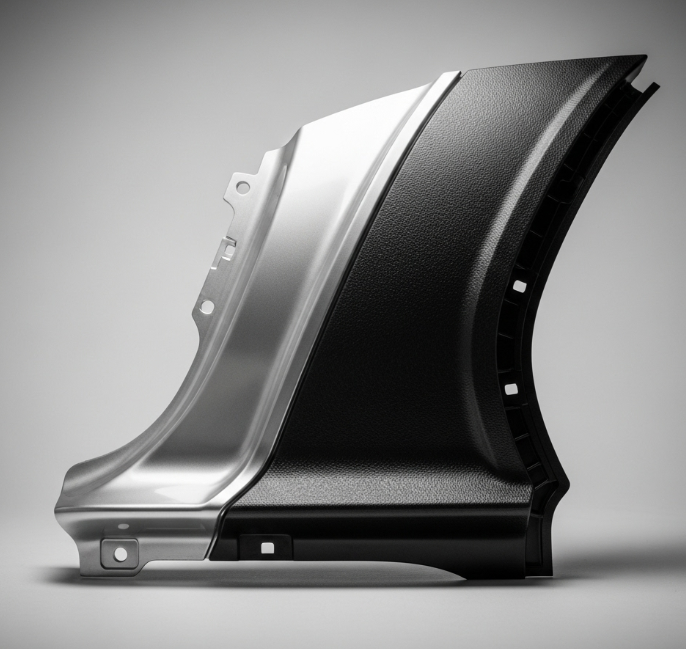

Exterior

As automobiles change, the requirements of their exterior change too. The need for lightweighting polymers and composites adoption has increased, whilst being able to cope with a broad range of environments from Scandanavia to the Middle-East. With changing styles, trends and technologies, exterior components have evolved from just being panels to being camera housings, sensor mounts and lighting features in addition to offering robust and aesthetically pleasing frames.

Applications

- Trims & spoilers

- Front grilles

- Roof and body panels

- Lighting

- Mirrors

- Sensor Housings

Exterior

As automobiles change, the requirements of their exterior change too. The need for lightweighting polymers and composites adoption has increased, whilst being able to cope with a broad range of environments from Scandanavia to the Middle-East. With changing styles, trends and technologies, exterior components have evolved from just being panels to being camera housings, sensor mounts and lighting features in addition to offering robust and aesthetically pleasing frames.

Applications

- Trims & spoilers

- Front grilles

- Roof and body panels

- Lighting

- Mirrors

- Sensor Housings

General

In the current transformation of the automotive industry, materials including plastics are key to optimising design, efficiency and sustainability. From lightweight components to enhance fuel economy to durable interiors that elevate comfort. Performance, safety and sustainability can all be achieved simultaneously with our advanced range of recycled and renewable feedstock plastics.

Applications

- Panels

- Climate control

- Safety systems

General

In the current transformation of the automotive industry, materials including plastics are key to optimising design, efficiency and sustainability. From lightweight components to enhance fuel economy to durable interiors that elevate comfort. Performance, safety and sustainability can all be achieved simultaneously with our advanced range of recycled and renewable feedstock plastics.

Applications

- Panels

- Climate control

- Safety systems

Interior

As the expectations of an automobile have changed over the years so has the expectations of its interior. Blending functional, aesthetics, longevity and style means that there is an increased pressure on polymers to meet these requirements. Add in to this the need for weight reduction and a focus on sustainability the types of polymers used in automotive has evolved to include a wide range of solutions.

Applications

- Seating components

- Instrumental panels and central consoles

- Loudspeaker grills

- Safety equipment

- Storage and Tables

- Switchgear

Interior

As the expectations of an automobile have changed over the years so has the expectations of its interior. Blending functional, aesthetics, longevity and style means that there is an increased pressure on polymers to meet these requirements. Add in to this the need for weight reduction and a focus on sustainability the types of polymers used in automotive has evolved to include a wide range of solutions.

Applications

- Seating components

- Instrumental panels and central consoles

- Loudspeaker grills

- Safety equipment

- Storage and Tables

- Switchgear

Underbonnet

The underbonnet of a car is subject to extreme conditions. Components in this area experience intense temperature fluctiations, exposure to various chemicals and mechanical stresses. The evolution of car engines to renewably powered alternatives means the demands of underbonnet applications are shifting. For battery electric vehicles, polymers must be able to withstand the high voltages for them to be safe and fit for purpose, whilst withstanding the fluctuating environmental temperatures and chemical exposure. Ultrapolymers works with it's supply partners to bring new polymer technologies to market and meet the demanding upcoming cases such as this.

Applications

- Engine covers

- Battery housings

- Engine ducting

- Grommets and connectors

Underbonnet

The underbonnet of a car is subject to extreme conditions. Components in this area experience intense temperature fluctiations, exposure to various chemicals and mechanical stresses. The evolution of car engines to renewably powered alternatives means the demands of underbonnet applications are shifting. For battery electric vehicles, polymers must be able to withstand the high voltages for them to be safe and fit for purpose, whilst withstanding the fluctuating environmental temperatures and chemical exposure. Ultrapolymers works with it's supply partners to bring new polymer technologies to market and meet the demanding upcoming cases such as this.

Applications

- Engine covers

- Battery housings

- Engine ducting

- Grommets and connectors

Electric Vehicle Applications

The largest growing segment within automotive is BEV (Battery Electric Vehicles) which has heralded a significant change in the material requirements for vehicles. Specialist polymers are having an increased need for use in these vehicles, compensating for the weight of a battery pack but also the safety and security needs for high voltage systems. Ultrapolymers partners with leading manufacturers of polymers designed with the demands of Electric Vehicles in mind.

Applications

- Battery cooling systems

- Battery Housings

- EV Drivetrains

- Charging components and high voltage connectors

Electric Vehicle Applications

The largest growing segment within automotive is BEV (Battery Electric Vehicles) which has heralded a significant change in the material requirements for vehicles. Specialist polymers are having an increased need for use in these vehicles, compensating for the weight of a battery pack but also the safety and security needs for high voltage systems. Ultrapolymers partners with leading manufacturers of polymers designed with the demands of Electric Vehicles in mind.

Applications

- Battery cooling systems

- Battery Housings

- EV Drivetrains

- Charging components and high voltage connectors