Post-Consumer Recycled LDPE for Cast Film & Blown Film Extrusion

Low density polyethylene (LDPE) films, used for heavy duty bags, agricultural films, and industrial and consumer packaging are now subject to new packaging regulations. This includes the PPWR (Packaging & Packaging Waste Regulation) which demands that by 2030, certain plastic packaging must contain ≈ 30% recycled content. How can you prepare and get ahead of the change?

Oceanworks® have a full range of polymer solutions for the film market, made from 100% post-consumer recycled (PCR) feedstocks. With a full suite of products of different melt flows, delivering stiffness, shrinkage, sealing, and cling properties, enabling you to formulate a complete multilayer solution from a single supplier.

Reducing your Environmental Footprint without Compromising on Quality

Often being what initially showcases the product, packaging makes the first impression on the consumer therefore needs to be robust for ease of transport, aesthetically appealing and with increasing consumer awareness of sustainability, present it's sustainability position.

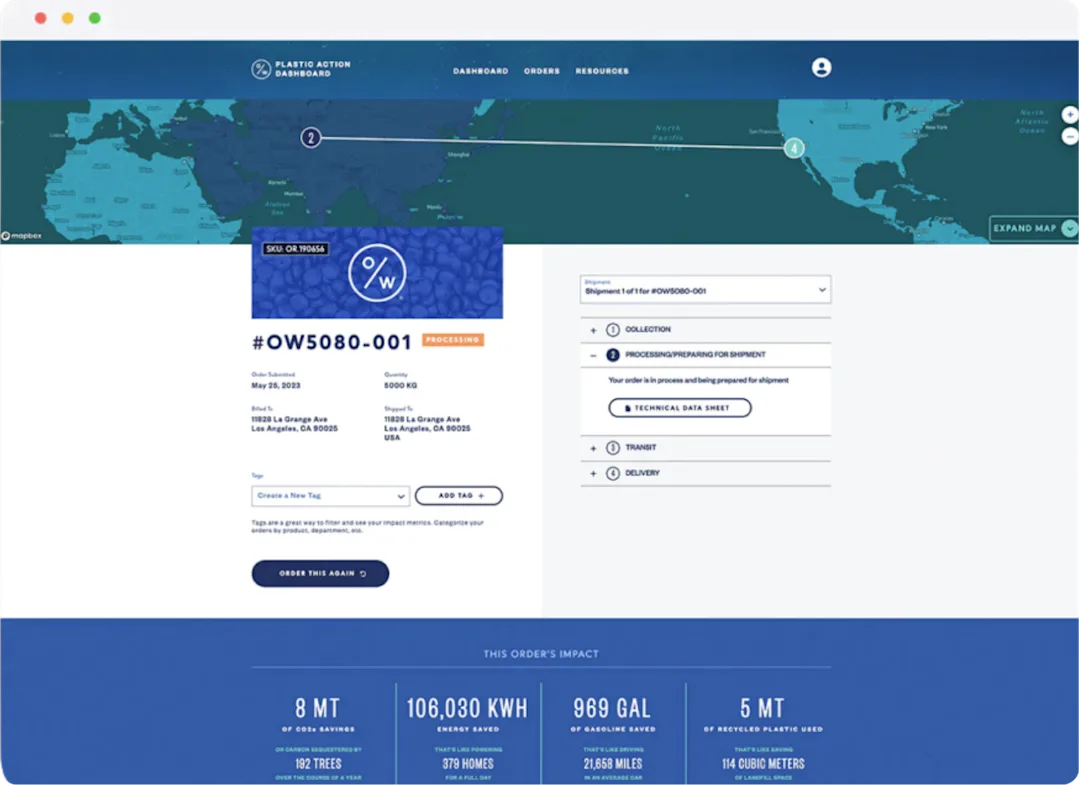

With Oceanworks® products, you can track where the material has originated from and receive data on your order's environmental impact.

Blown Film Extrusion Polyethylene

Collation Shrink Films

Collation shrink films, for the bundling of items such as drinks bottles, tins and cans. LL/LDPE materials from Oceanworks® offer a cost effective solution that can be used in conjunction with LDPE PCR.222644(.02) with shrinkage properties, and HDPE grades to add stiffness to the final product.

Heavy Duty & Form Fill Seal (FFS) Bags

Heavy duty & FFS bags, for washing detergent capsules, compost, fertilisers and building materials. Alongside cost effective LL/LDPEs, Oceanworks® have the LLDPE PCR.222641(.02) for sealability, LDPE PCR.222644(.02) for ease of processing and HDPE grades for added stiffness.

Shrink Hoods, Liners & Mulch Films

Shrink hoods, liners and mulch films used in transportation of goods and the agricultural industry. Again Oceanworks® offer a full package with LDPE PCR.222644(.02) for shrinkage, LL/LDPE PCR.222643 for resistance , HDPE for stiffness and standard cost effective LDPEs .

New Specialised Recycling Plant in Europe

In Q1 of 2026, Oceanworks will open their first production site in Europe. Located in Prague, the new site will produce entirely recycled grades for film applications.

The new custom recycling line has been carefully designed by highly experienced thought leaders in the industry with a tailor made screw that facilitates a soft extrusion process. Soft extrusion allows the material to be processed at a lower temperature, minimising the occurrence of gels and producing a high quality, reliable product with excellent batch-to-batch consistency.

Alongside this, new contracts are being signed for European sourced feedstocks that will ensure good availability and quick lead times.

Cast Film Extrusion PP & PE

Where have our customers successfully used Oceanworks® LDPE

Please sign in with your Ultrapolymers account to access this information

Use the button below to continue.